In today’s industrial landscape, where efficiency, safety, sustainability, and flexibility define success, plant engineering serves as the backbone of progress. It is a multidisciplinary field that integrates mechanical, electrical, civil, process, and automation engineering to design, construct, operate, and maintain industrial plants across sectors such as chemicals, pharmaceuticals, food and beverage, and energy. From conceptualization to commissioning, every stage of plant engineering plays a crucial role in ensuring that complex systems perform seamlessly and sustainably.

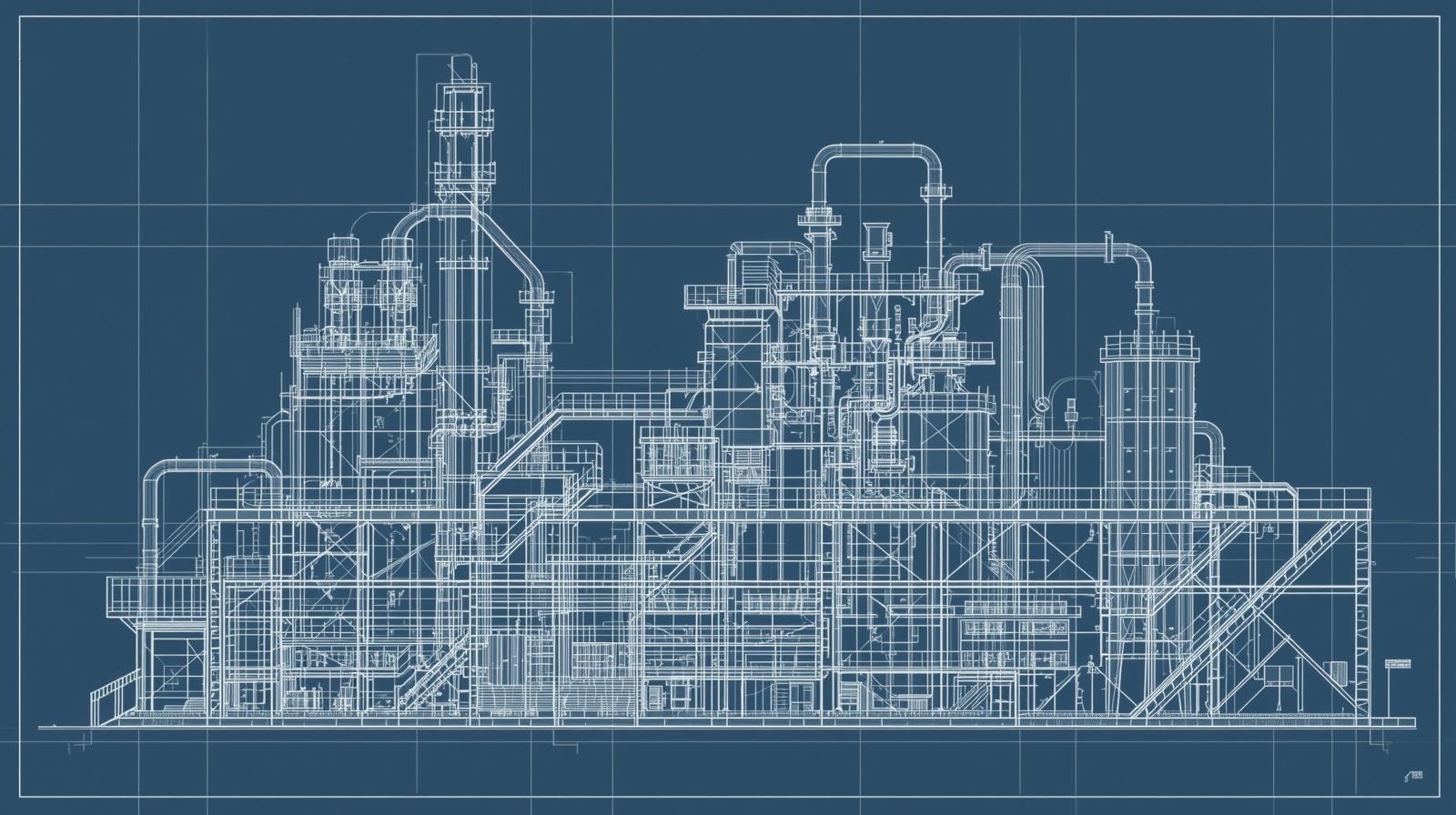

A typical plant engineering project begins with the feasibility and conceptual design stage, where process requirements, capacities, and constraints are analyzed to create high-level layouts and estimates. This is followed by Front-End Engineering Design (FEED), during which process flow diagrams (PFDs), piping and instrumentation diagrams (P&IDs), and equipment specifications are developed. The detailed engineering phase integrates all disciplines—mechanical, electrical, civil, instrumentation, and control—ensuring every aspect of the plant aligns with performance goals, safety standards, and regulatory requirements. Once the designs are finalized, procurement and fabrication begin, involving vendor selection, quality checks, and manufacturing oversight. The construction and installation phase then brings the plant to life through equipment erection, piping, wiring, and civil works. Finally, commissioning and start-up activities ensure that each system operates as intended before the plant enters full-scale production.

Despite technological advances, plant engineering continues to face several challenges. Coordination across multiple engineering domains remains complex, as a design change in one area can significantly affect others. Managing vast amounts of documentation, ensuring compliance with safety and environmental standards, controlling costs, and integrating new technologies with legacy systems further complicate project execution. Additionally, rapid innovation in digital and automation technologies requires engineering teams to continuously update their skills and adapt to evolving industry practices.

To overcome these challenges, plant engineering is undergoing a digital transformation. Tools such as digital twins and simulation software are enabling engineers to create virtual replicas of plants for predictive maintenance and performance optimization. The integration of IoT and Industry 4.0 technologies allows for real-time monitoring and data-driven decision-making, while modular and skid-mounted designs accelerate construction timelines and improve quality control. Sustainability has also become a fundamental aspect of plant design, with growing emphasis on energy efficiency, waste reduction, and renewable resource utilization. Meanwhile, the use of artificial intelligence (AI) and machine learning (ML) helps predict equipment failures, optimize operations, and streamline maintenance activities. Augmented reality (AR) and virtual reality (VR) are also revolutionizing commissioning and maintenance, providing immersive, guided visualizations for technicians. Additionally, Building Information Modeling (BIM) and 4D/5D modeling are being adopted to synchronize design geometry, cost, and schedule—resulting in fewer errors and more predictable project outcomes.

Success in plant engineering relies on a few fundamental best practices. Early involvement of all stakeholders—from operations and safety to procurement—ensures that design decisions reflect real-world needs. Modular design and standardization help minimize customization and simplify maintenance. Digital platforms unify data across the design, procurement, and construction phases, reducing silos and rework. A structured change management process maintains design integrity even when late-stage modifications arise. Furthermore, embedding sustainability considerations from the very first stage of design ensures that plants are energy-efficient, environmentally compliant, and cost-effective over the long term.

Consider, for example, a food-processing plant expansion project. By leveraging modular skids, digital twins, IoT sensors, and AR-assisted commissioning, engineers can drastically reduce installation time and improve system reliability. Such integration not only ensures faster commissioning but also enables continuous optimization throughout the plant’s lifecycle—transforming it into a smart, efficient, and sustainable facility.

Ultimately, plant engineering is no longer limited to traditional design and construction; it has evolved into a strategic function that drives industrial competitiveness. By embracing digital transformation, sustainability, and integrated collaboration, engineering teams can create plants that are safer, smarter, and ready for the challenges of tomorrow.