In today’s rapidly evolving industrial landscape, plant engineering is more than facility design—it’s the backbone of operational excellence. TechPennar, a specialist business unit of Pennar Industries Limited headquartered in Hyderabad, brings deep multidisciplinary expertise to every stage of the plant engineering lifecycle: from basic to detailed engineering, installation‑commissioning support, and as‑built documentation.

Understanding Plant Engineering

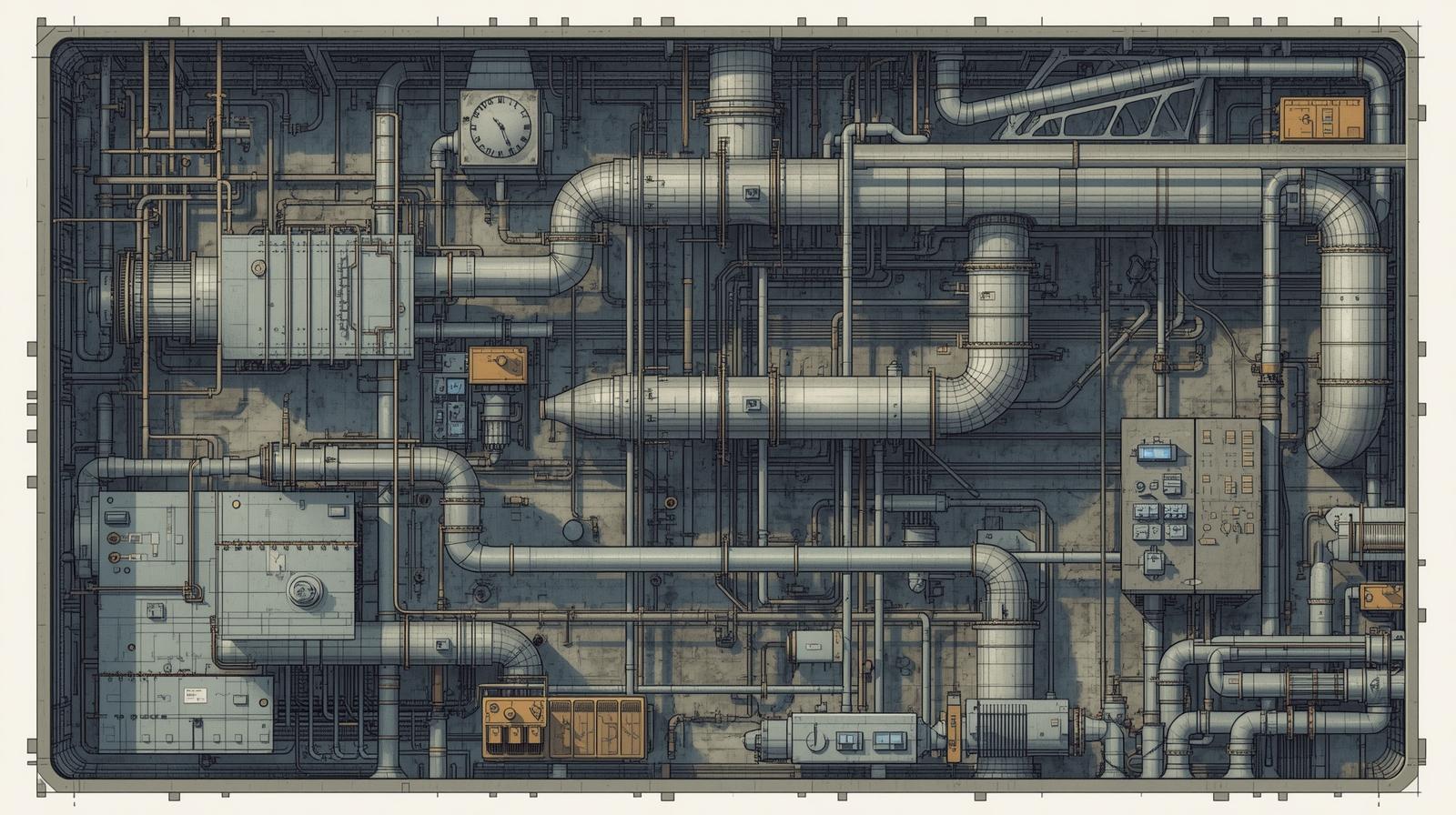

While product engineering focuses on individual product development, plant engineering aims at designing and optimizing the entire production process—improving throughput, reducing bottlenecks, and ensuring consistent quality. It demands coordination across civil, structural, mechanical, piping, electrical, instrumentation, and control systems.

Within plant engineering, disciplines like process flow design, layout planning, automation, regulatory compliance, and commissioning are brought together into one cohesive system. Process integration techniques—such as pinch analysis—further align unit operations to optimize energy usage, reduce cost, and enhance sustainability.

TechPennar’s Comprehensive Approach

TechPennar’s plant engineering service portfolio emphasizes a structured and integrated lifecycle approach:

-

Concept & detailed engineering across multiple disciplines, including structural steel, piping, controls, and automation

-

Installation and commissioning support, with as‑built documentation to ensure operational clarity

-

Value engineering embedded throughout to maximize efficiency while minimizing cost

This multi‑disciplinary capability allows TechPennar to work across energy, heavy engineering, process industries (like food & beverage, pharma, mineral processing), infrastructure, and material handling industries.

Lifecycle Excellence & Digital Integration

Leading plant engineering approaches today prioritize digital continuity—from design through operation. TechPennar provides 3D CAD modeling, installation drawings, documentation, and bill of materials that seamlessly integrate with manufacturing and maintenance workflows.

Such tools enable better communication among engineering, operations, and supply teams, supporting faster commissioning, accurate BOM creation, and efficient facility handovers—key to reducing rework and streamlining start-up.

Why It Matters

A well-engineered plant delivers benefits that resonate across the enterprise:

-

Operational reliability through robust design and preventive maintenance readiness

-

Cost efficiency via optimized layout, energy use, and reduced downtime

-

Regulatory compliance via integrated designs for emissions control, safety, and environmental standards

-

Scalability and flex‑capacity, enabling quick adaptation to new products, processes, or increased volume

TechPennar’s emphasis on sustainable engineering solutions and value-added process optimization ensures clients get not just a facility, but a future‑ready production ecosystem.

Case in Point: End‑to‑End Delivery

Imagine a process‑industry plant project: from early-stage layout and piping design to installation drawings, control system integration, and final commissioning. TechPennar handles every phase. Its expert teams ensure civil and detailed mechanical design align with operational workflows, while control and automation systems minimize manual intervention—delivering a plant that runs safely, reliably, and efficiently.